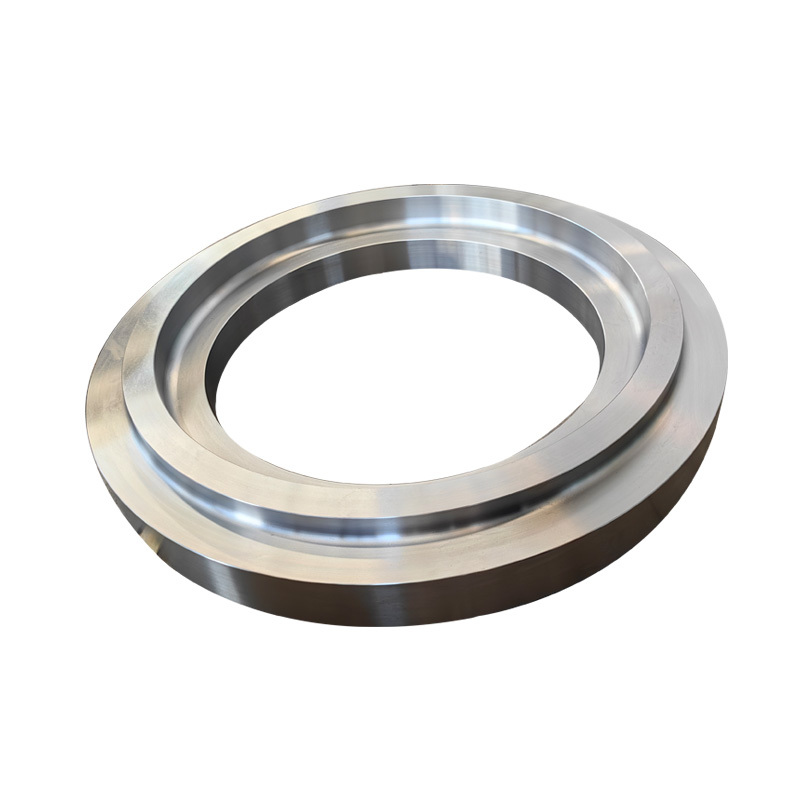

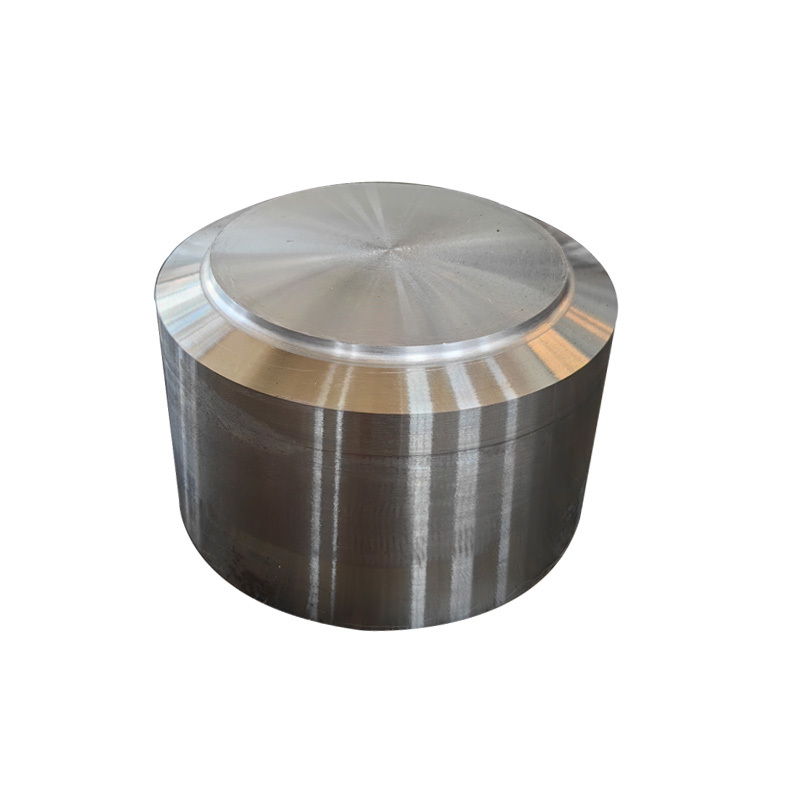

Blind plate forgings

Category:

Product Introduction

Product Parameters

Product name: Customized flange

Processing customization: Yes

Packing specification: individually packed

Surface treatment: polishing

Processing form: to map custom

Scope of application: mechanical processing

Processing cycle: 8-16 days

Product model: can be customized

Commonly used materials: various carbon steel, alloy steel, stainless steel, etc.

Carbon steel: A105, Q235, Q355D, 16MN, Q345B/C/D, 10#, 20#, 35#40#, 45#, 50#, 60#, etc

Stainless steel: 304LN, 316LN, 1CR13, 2CR13, 3CR13, 4CR13, 321, 302, etc. Alloy steel: 12CRMOV, 15CRMO, 20CRMO25CRMO, 30CRMO, 35CRMO42CRMO, 4140, 4340, 4330, 4130, 4150, 12CR2MO1, 9CR2MO17ICRMO6-4, CRIMNIM40NIM30MO, 34MO, etc

Die steel: 4CR13, 3R17MO, 5CRNIMO, 5CRMNMO, 4CR2NIMOV, S7H10, H11, H12, H13, etc

Our Purpose

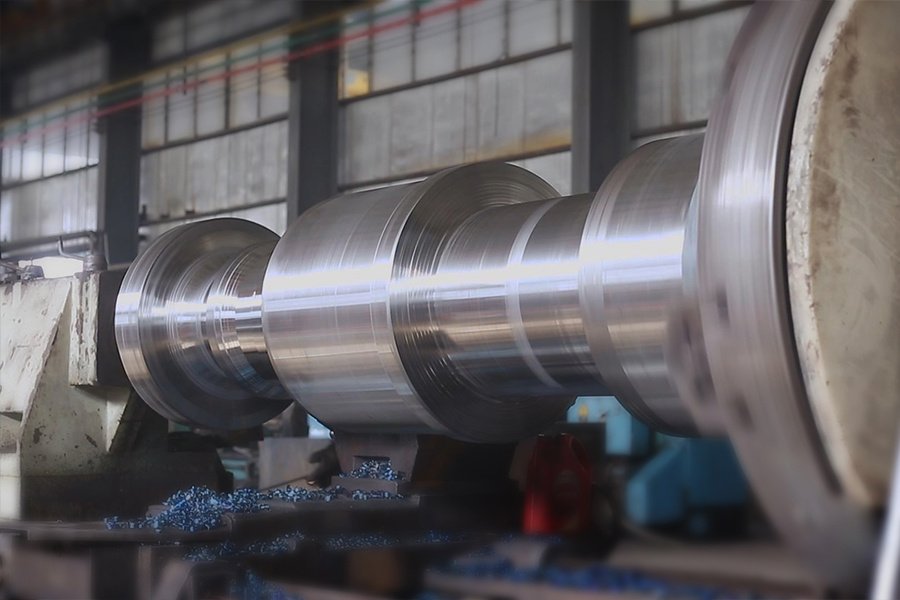

Process flow

(1) incoming inspection: a appearance inspection; B material list review; C chemical element analysis; D electroslag remelting

(2) block inspection: a weight accounting; B dimensional inspection; C quantity confirmation

(3) heating: a temperature control; B time control; C furnace installation quantity; D process analysis

(4) Forging inspection: A quantity inspection; B appearance inspection; C dimensional inspection; D weight inspection; E metallographic analysis

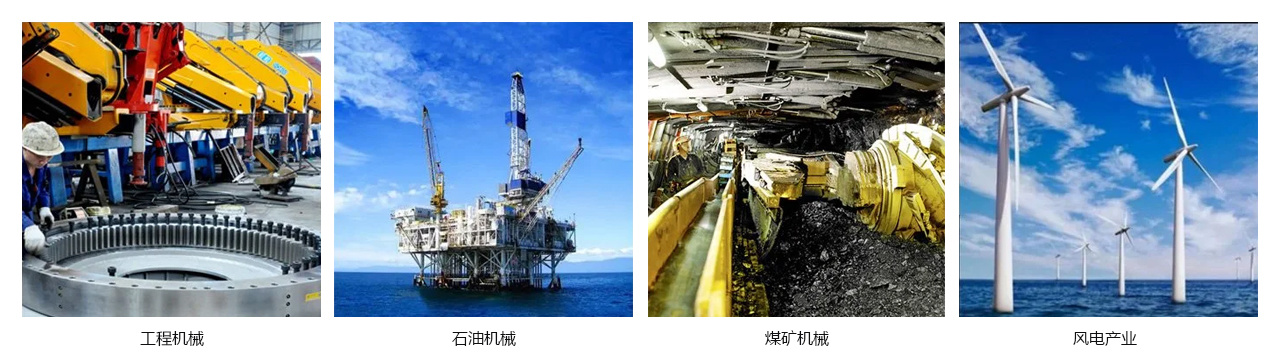

Scope of application

Production strength

Key words:

Online consultation

Related Products